Warpverter

A Serious Electronic Project For The Expert DIYer

Transformer Winding

If you’ve ever wanted to know how you could wind a toroidal transformer at home and without a fancy winder … there are a few options.

Some people use an empty solder reel or something similar to fill up with copper wire … though they don't generally hold much and can require refilling ... and then joins will be needed before the winding is finished. As the hole gets smaller it can become too small to fit the reel through.

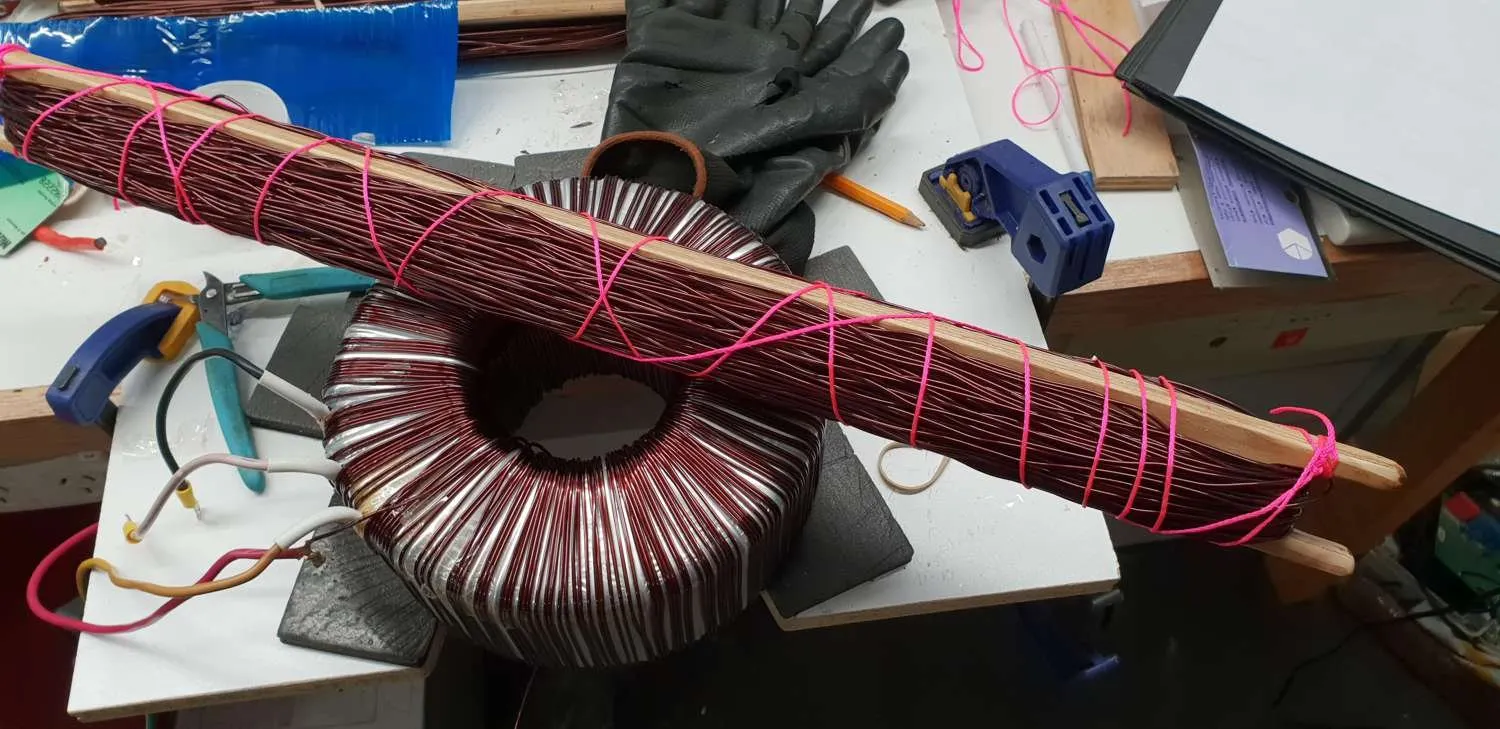

Others use a “shuttle” … a length of wood with a V in each end, with the copper wire wound on it to feed through the hole. As the hole fills up, that also gets harder to fit through and you may end up having to join on extra wire to make the distance … though extra long shuttles can fit a lot of wire.

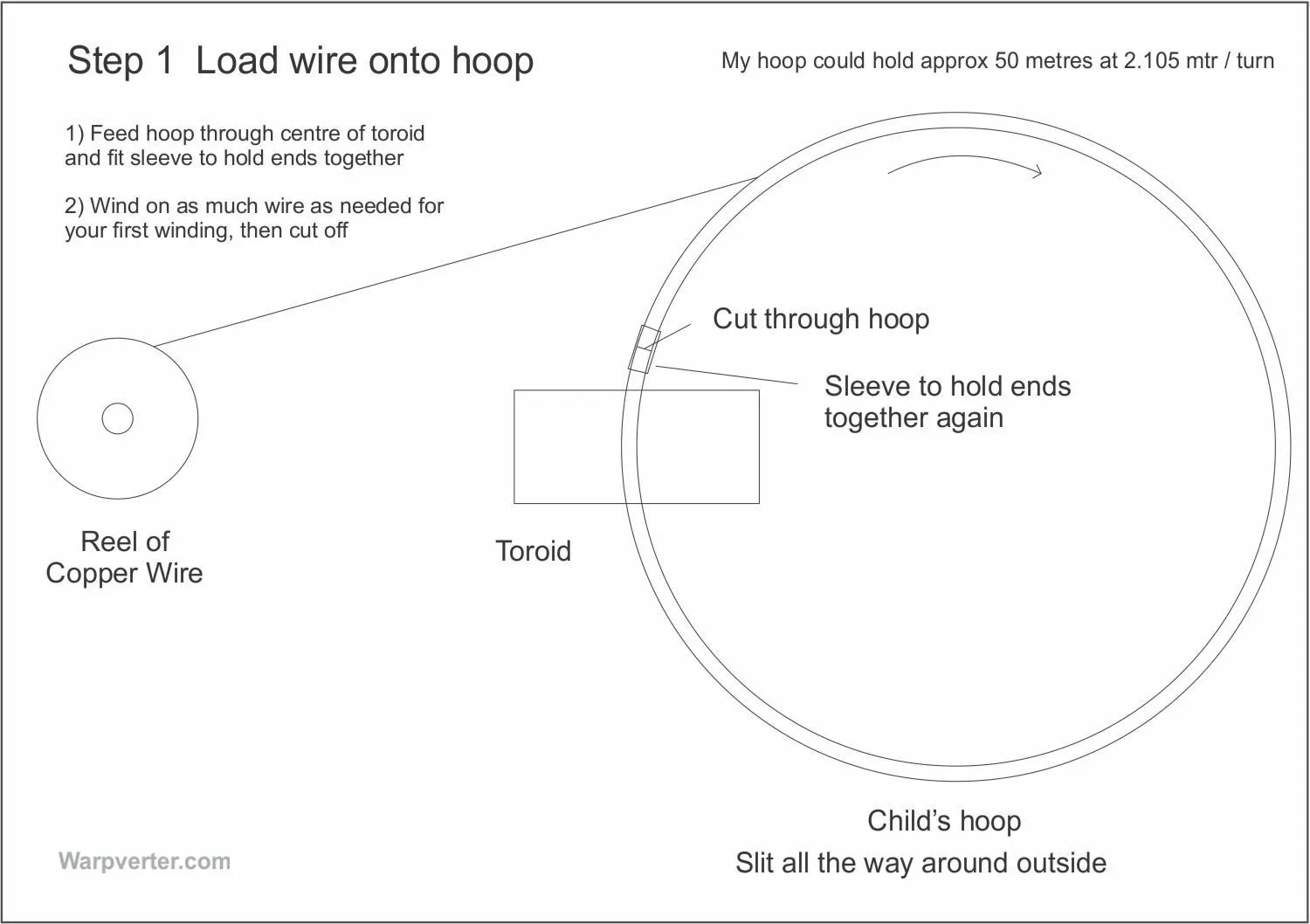

I prefer a third method … using a hoop. A kids hula hoop to be exact.

I used a Dremel to cut a slot all the way around the outer circumference ... though a hacksaw or fine bladed hand saw would work just as well.

The next step was to cut the hoop so I could pass it through the toroid centre … then found a short piece of plastic tube that would hold the two ends of the hoop together again. That also needs a matching slot.

I drilled a small hole through the inside of the hoop near the join so I can anchor the copper wire that I wind on..

The next step is to wind on the length of wire you need for your toroid winding … and I cover the sharp end of the wire with a bit of tape so I won’t get cut, or damage the insulation or wire on the core as I rotate it through.

Knowing the correct length is not as hard to work out as you may think … as you simply measure the distance around the toroid and multiply by the number of turns to get the wire length needed.

You know the hoop circumference, so work out how many turns on the hoop are needed.

Of course it pays to add some extra as it’s a lot easier to cut some off than to join some on … but it’s surprising how accurate you can be.

I’d count the number of turns as I rotated the hoop, and cut off the wire.

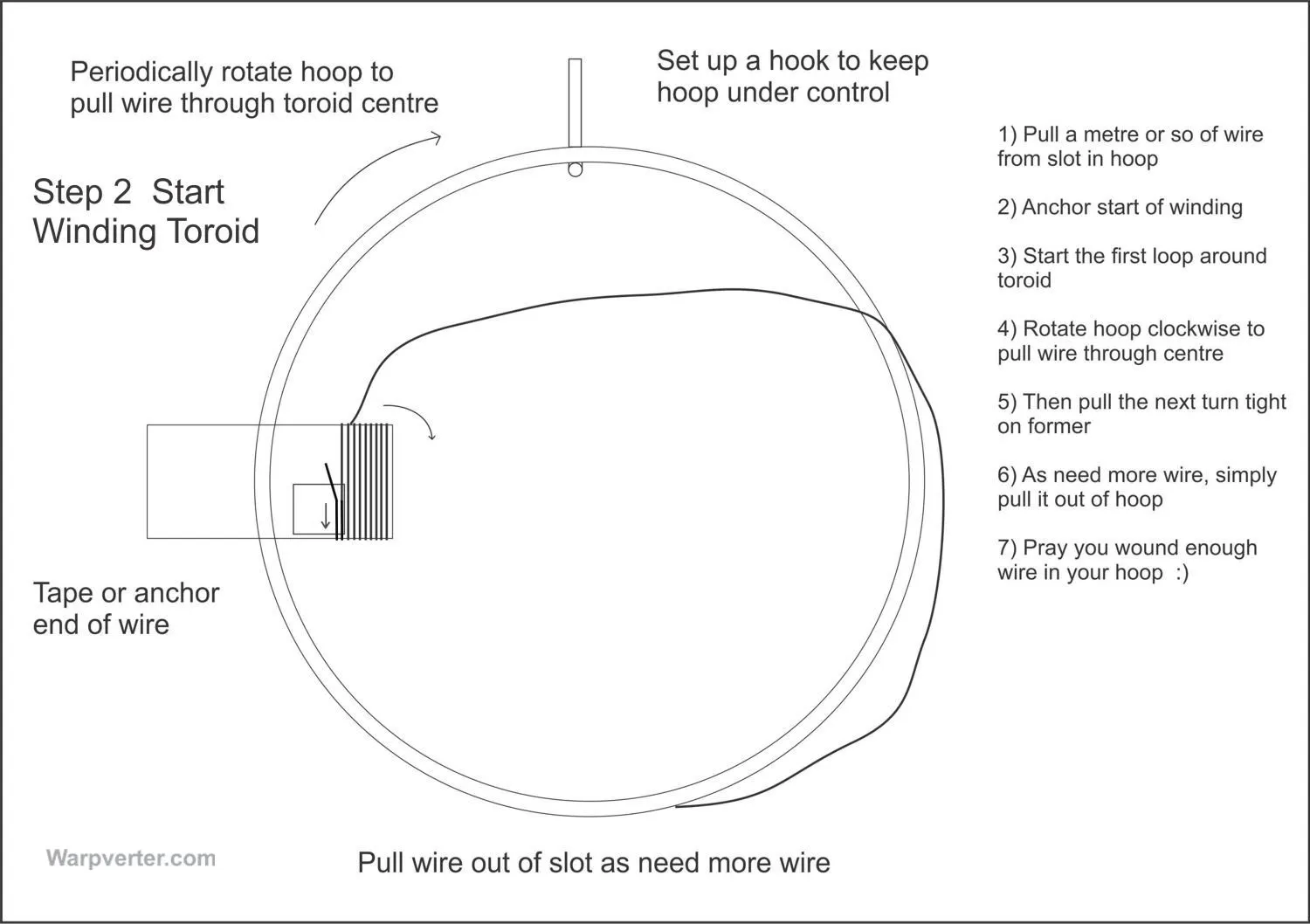

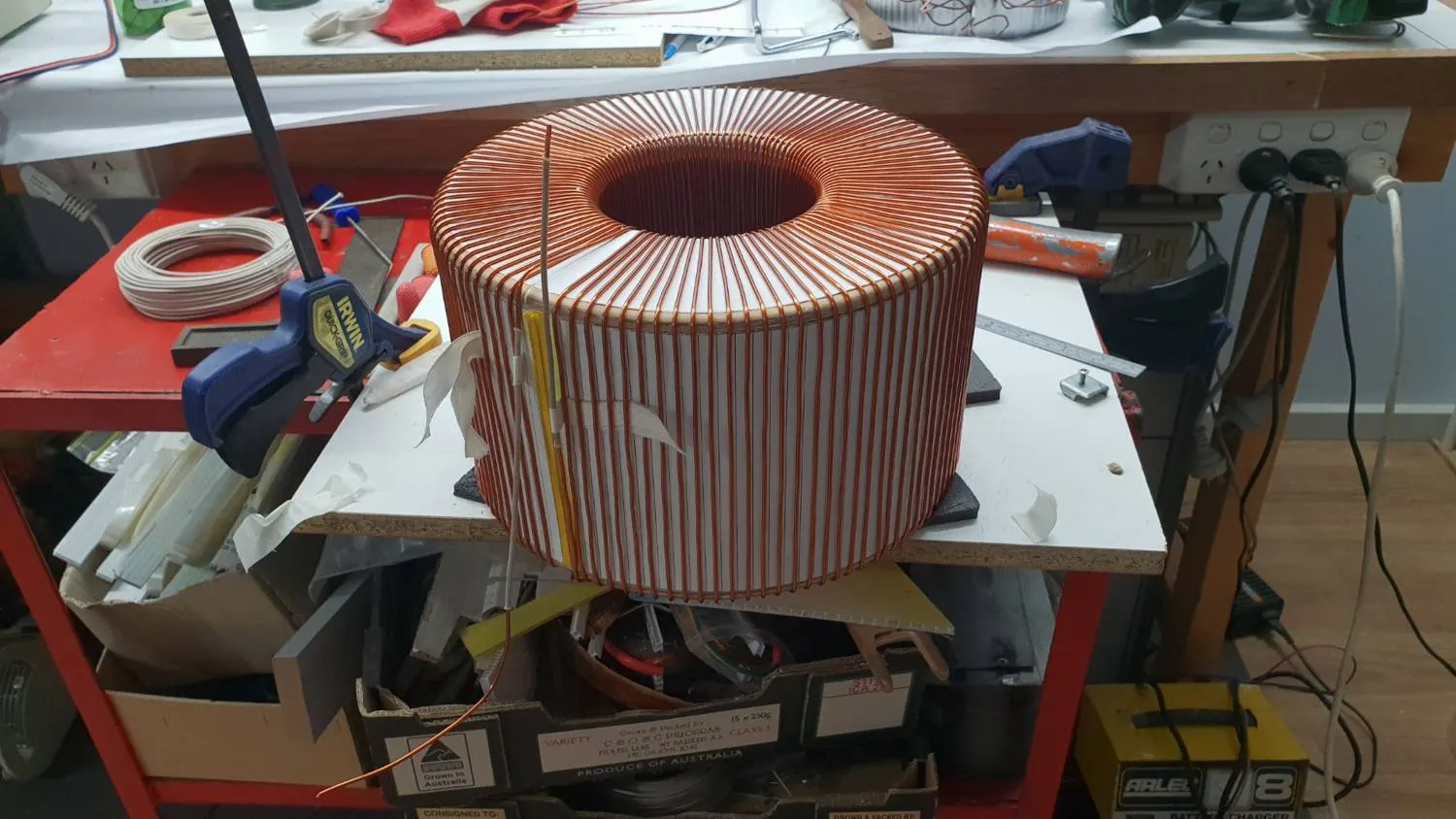

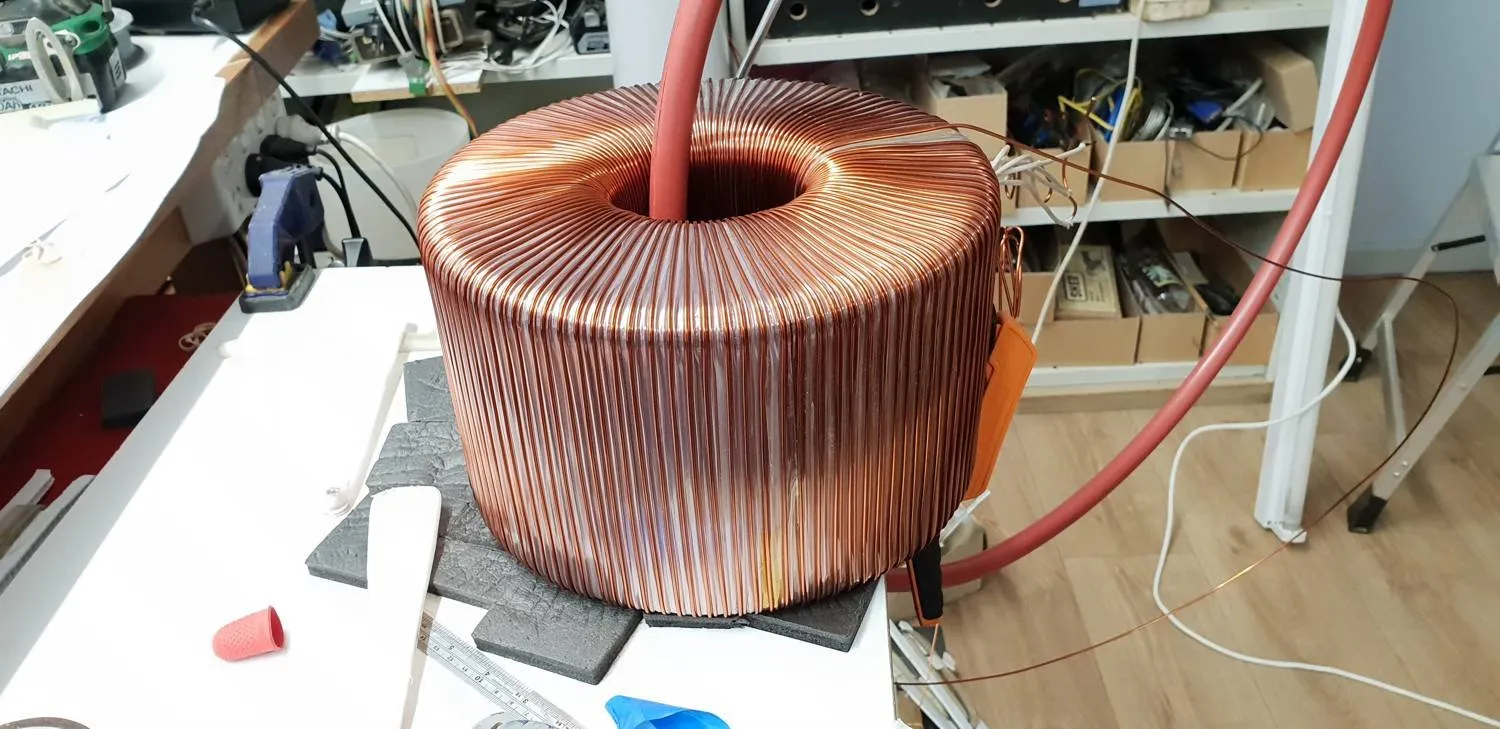

Then start the winding process on the toroid.

It can be difficult to visualise … but once you see it done and get a start, it becomes an easy job to do.

You need to pull the wire tight and keep it as lined up as possible … and as you use up the slack, you peel another turn out of the hoop and keep going.

The slotted hula hoop works really well as the plastic is quite rigid and the wire won't just fall out ... it needs to be peeled out as needed. I had tried an open hoop earlier, a bicycle rim ... but that needed tape to stop it coming loose and tangling up. Painful to have to untape and retape every loop you pull off.

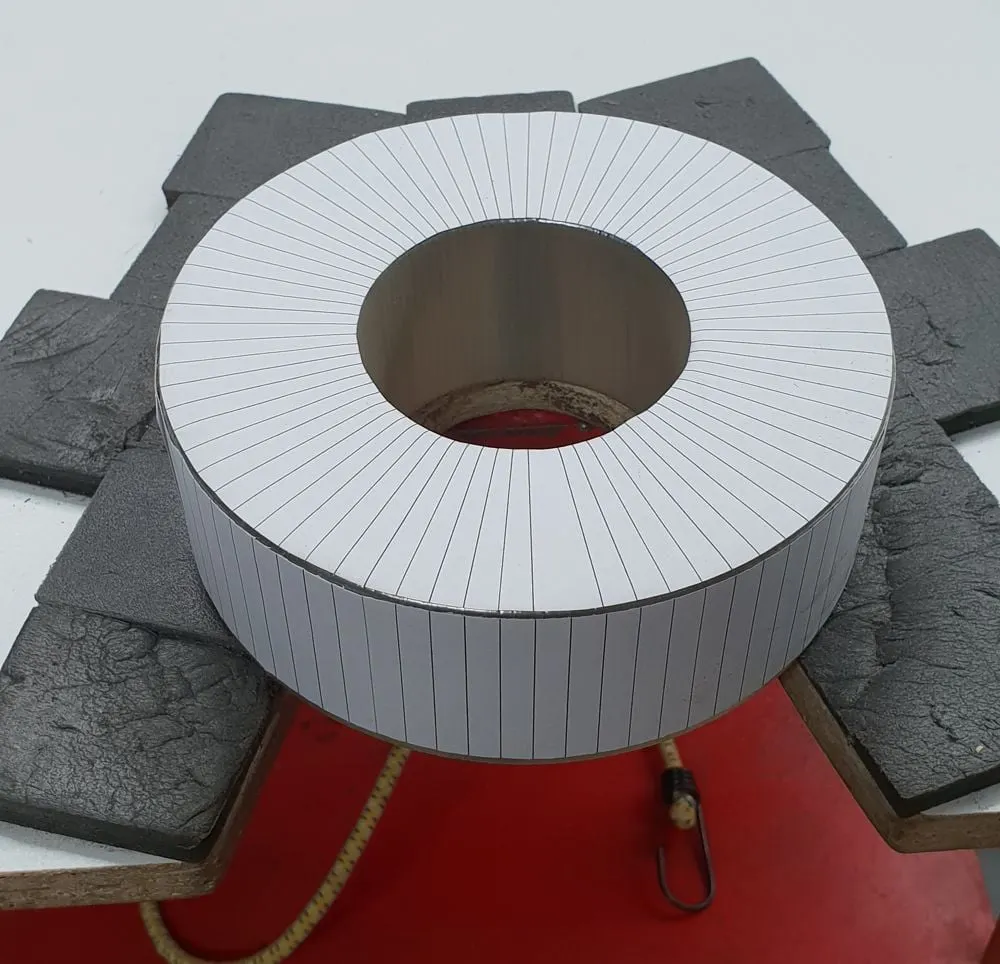

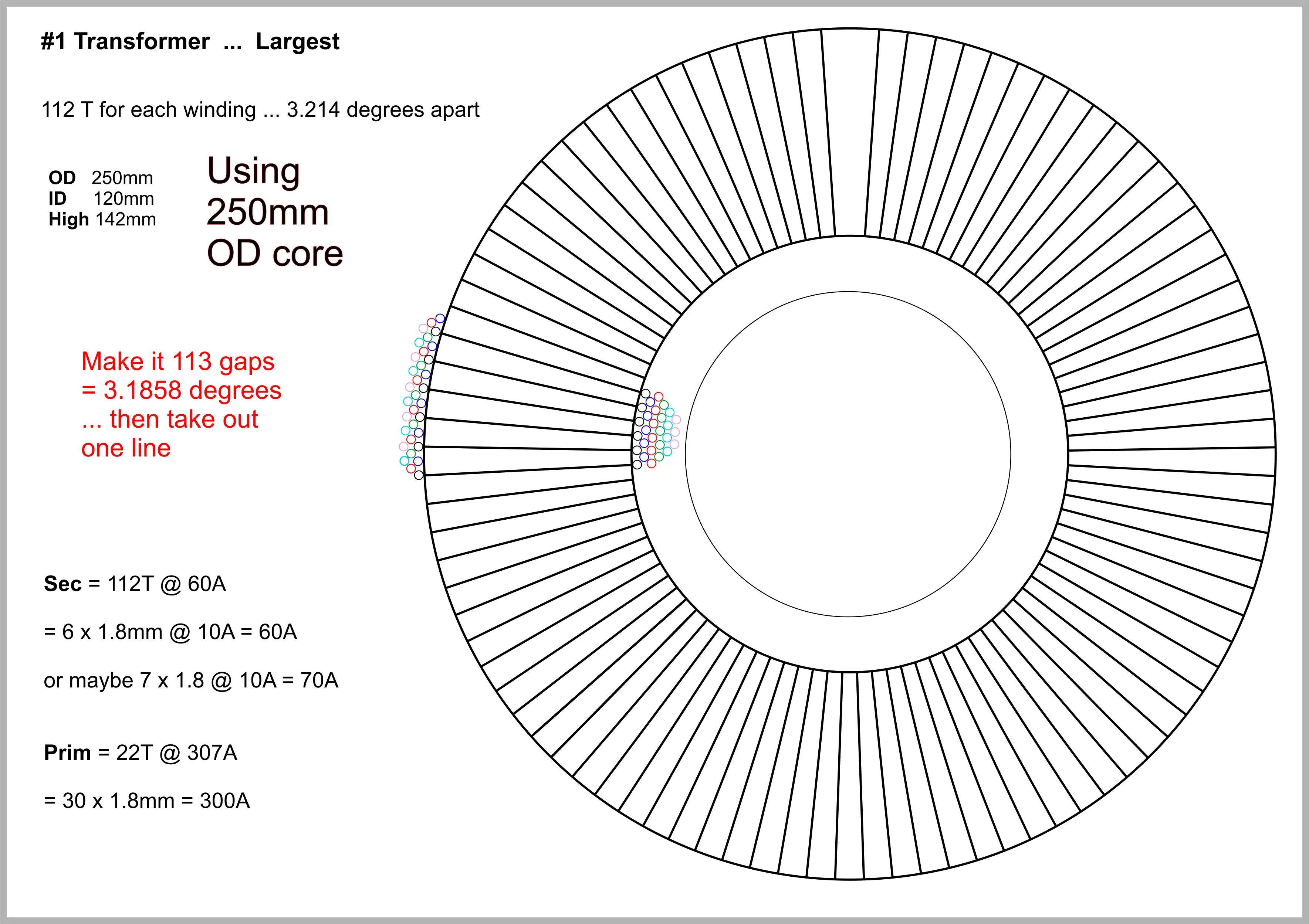

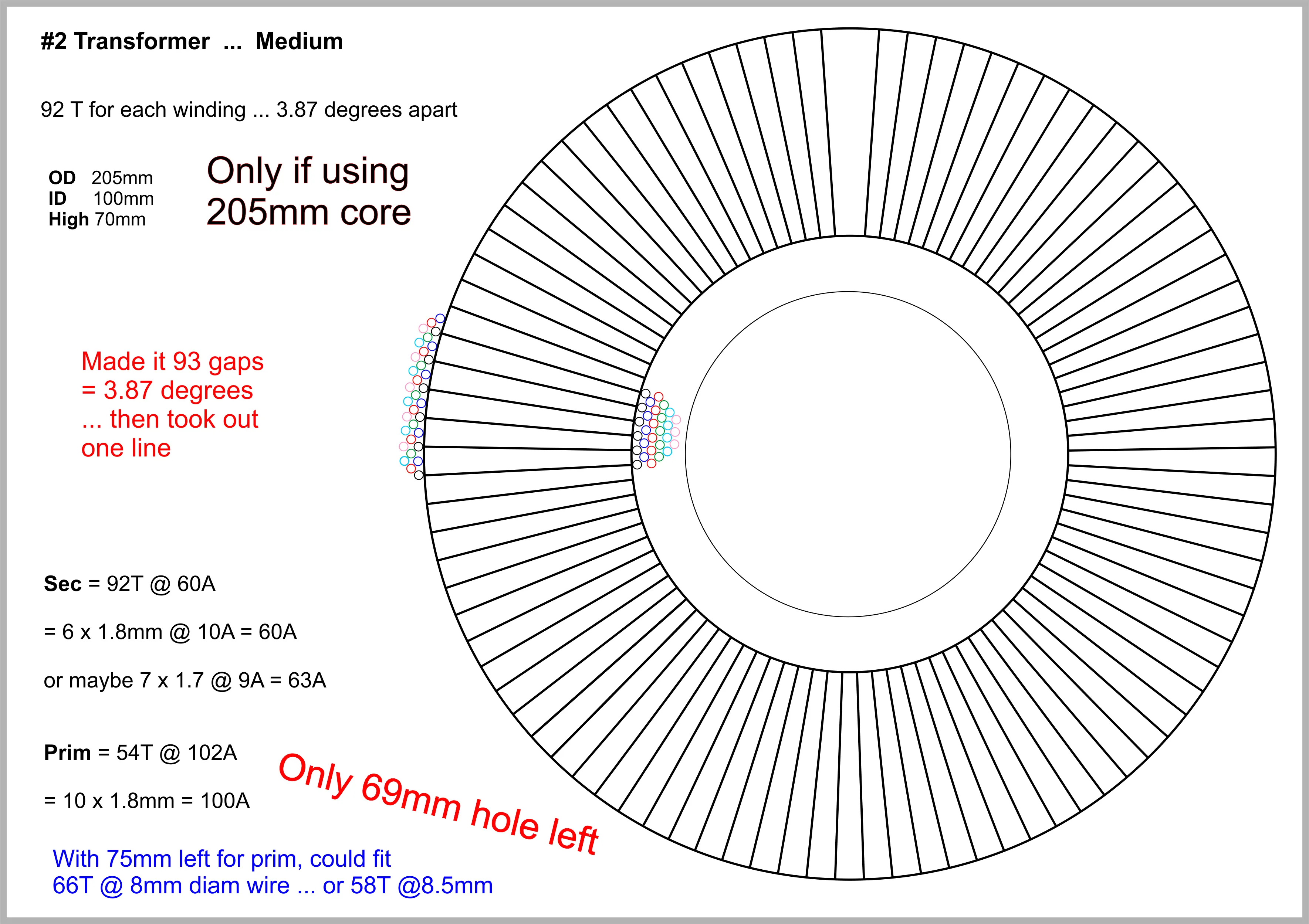

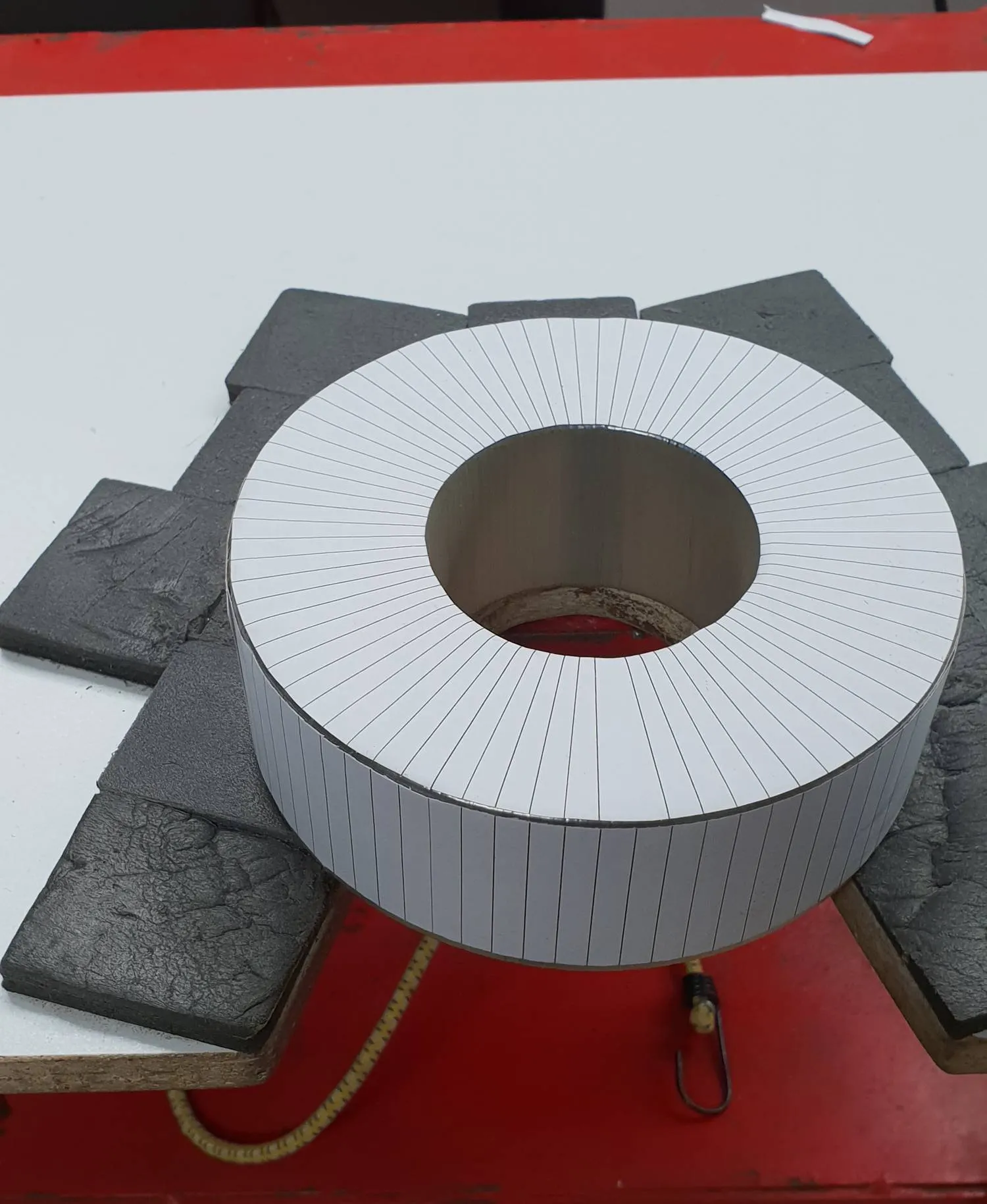

If you’re looking for a really neat and tidy wind, I found it helps to print a template so you know what spacing to use, to make your windings as neat as possible.

The neater and more consistent your first layer … the better, and quicker the subsequent windings will fall into place.

It may pay to wind mylar tape over each layer … to improve the insulation between layers … though that can reduce the hole size considerably, especially if there are a lot of layers.

If anyone has any questions, feel free to contact us and we can provide more information and add it here.

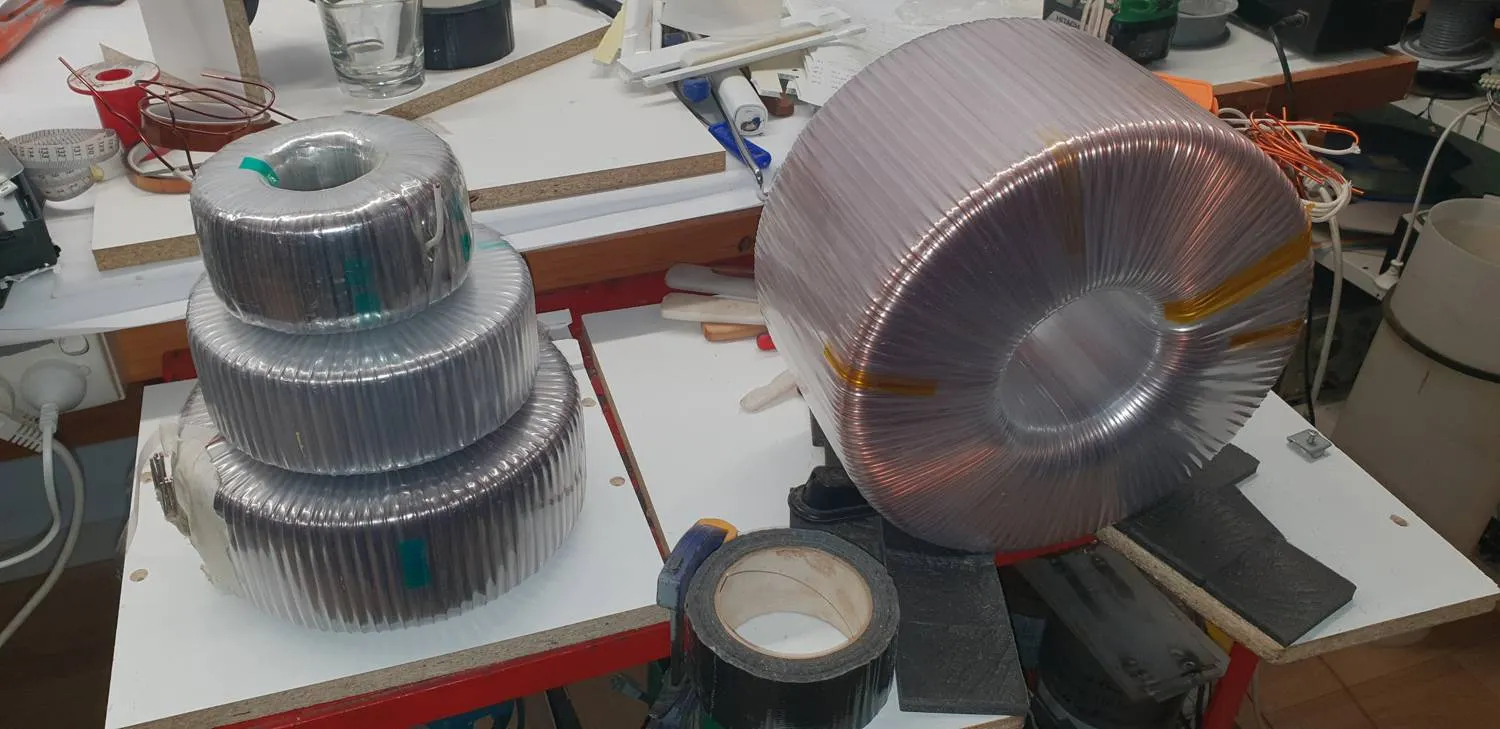

Some Random Photos

Click on photos to open enlarged versions

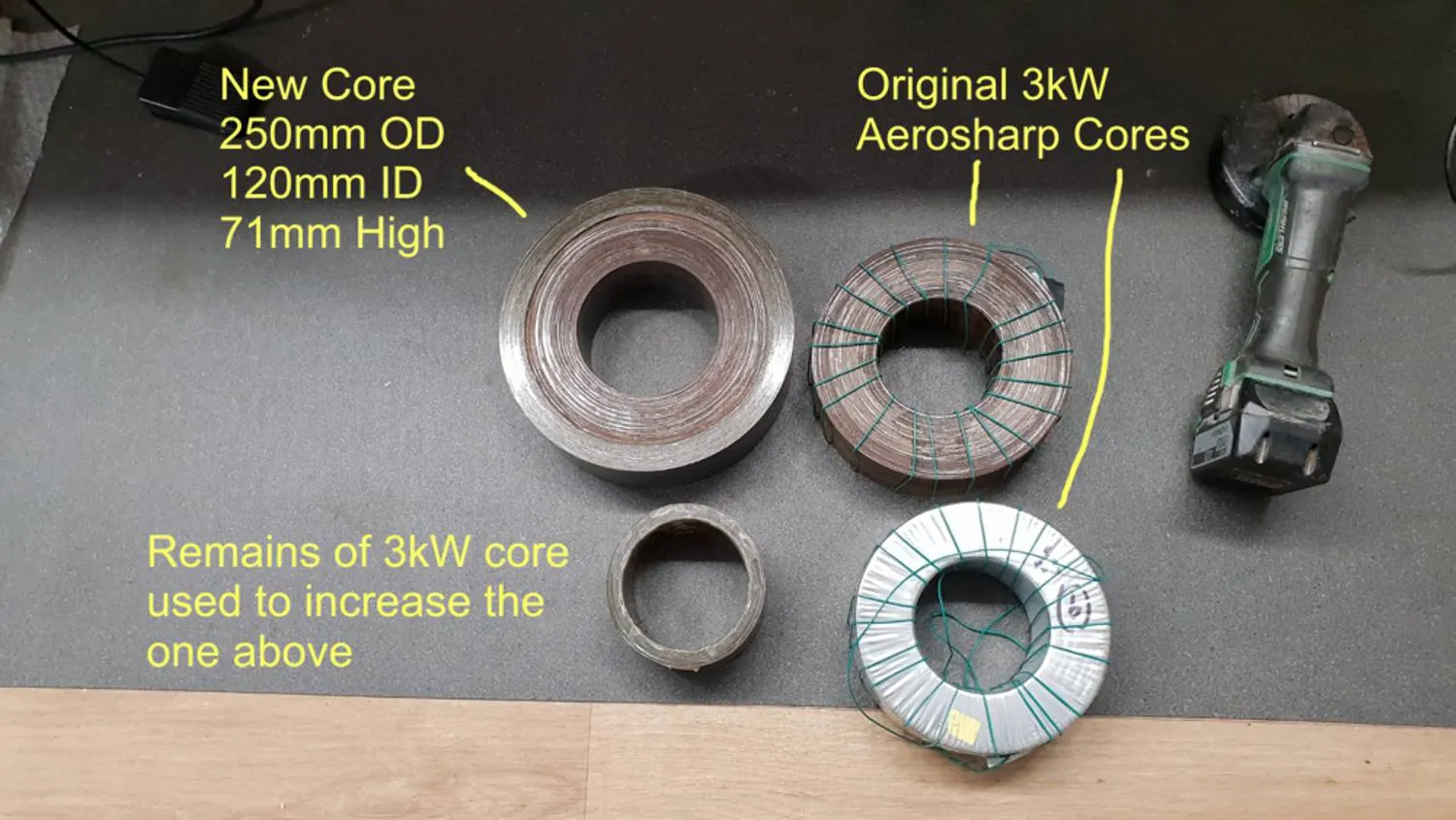

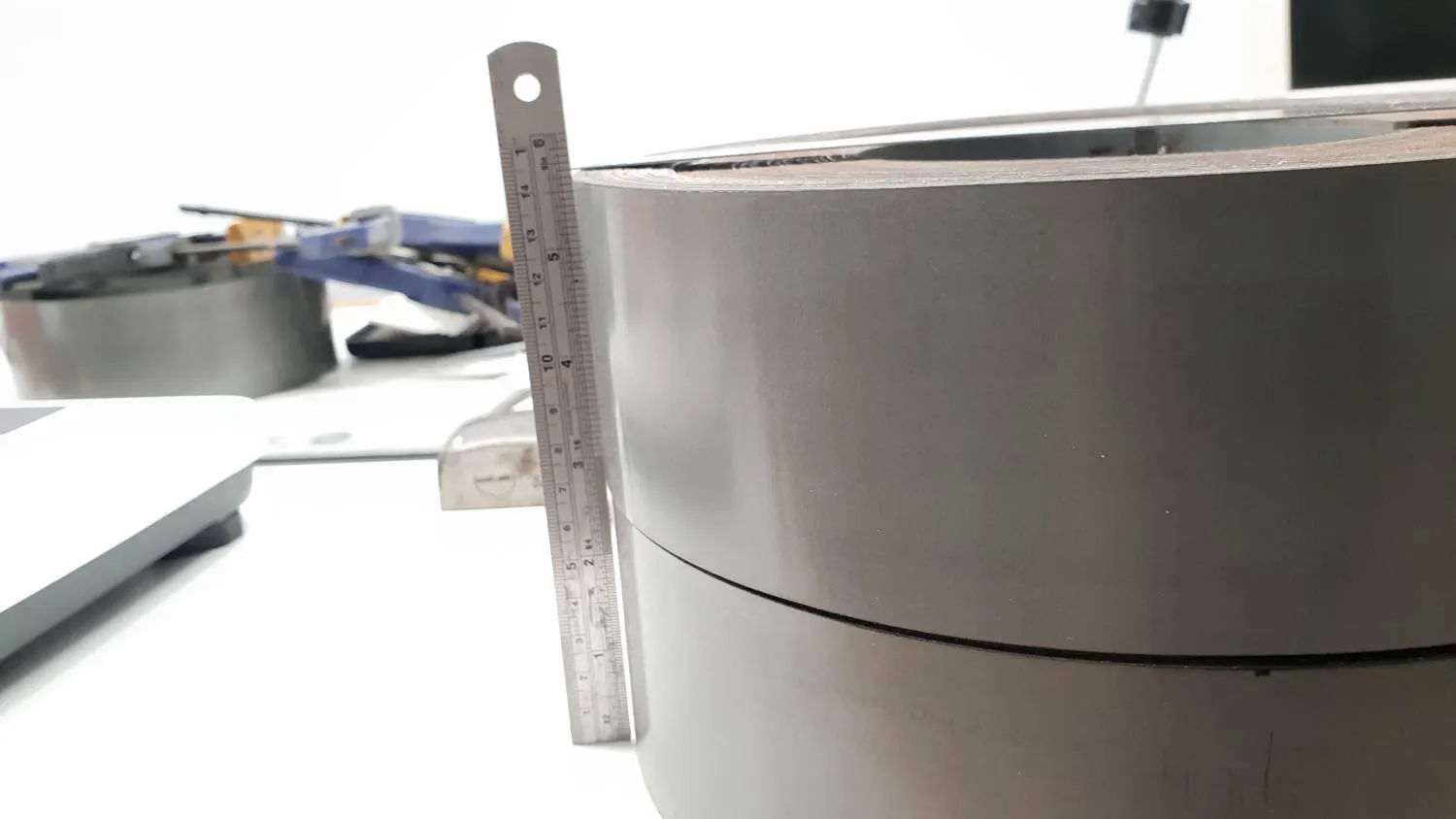

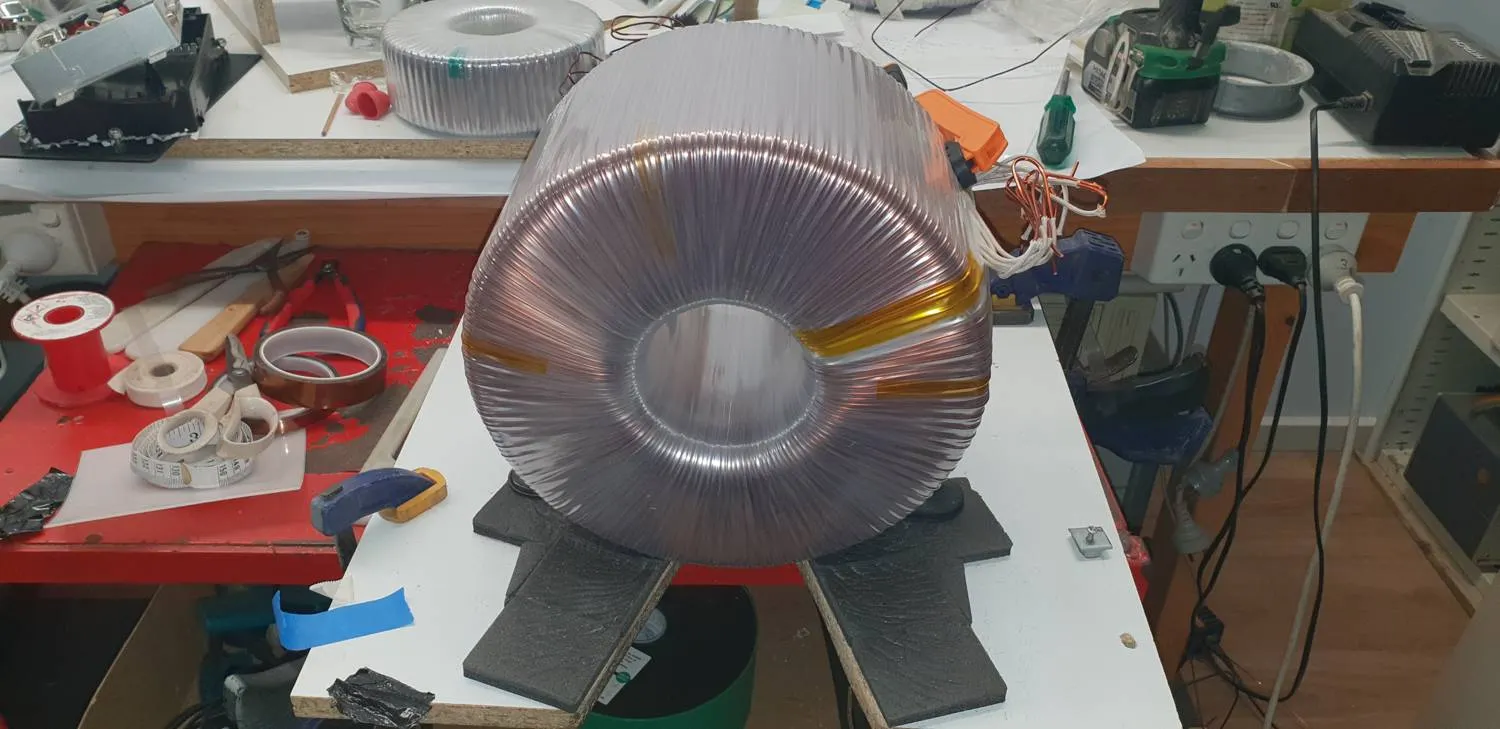

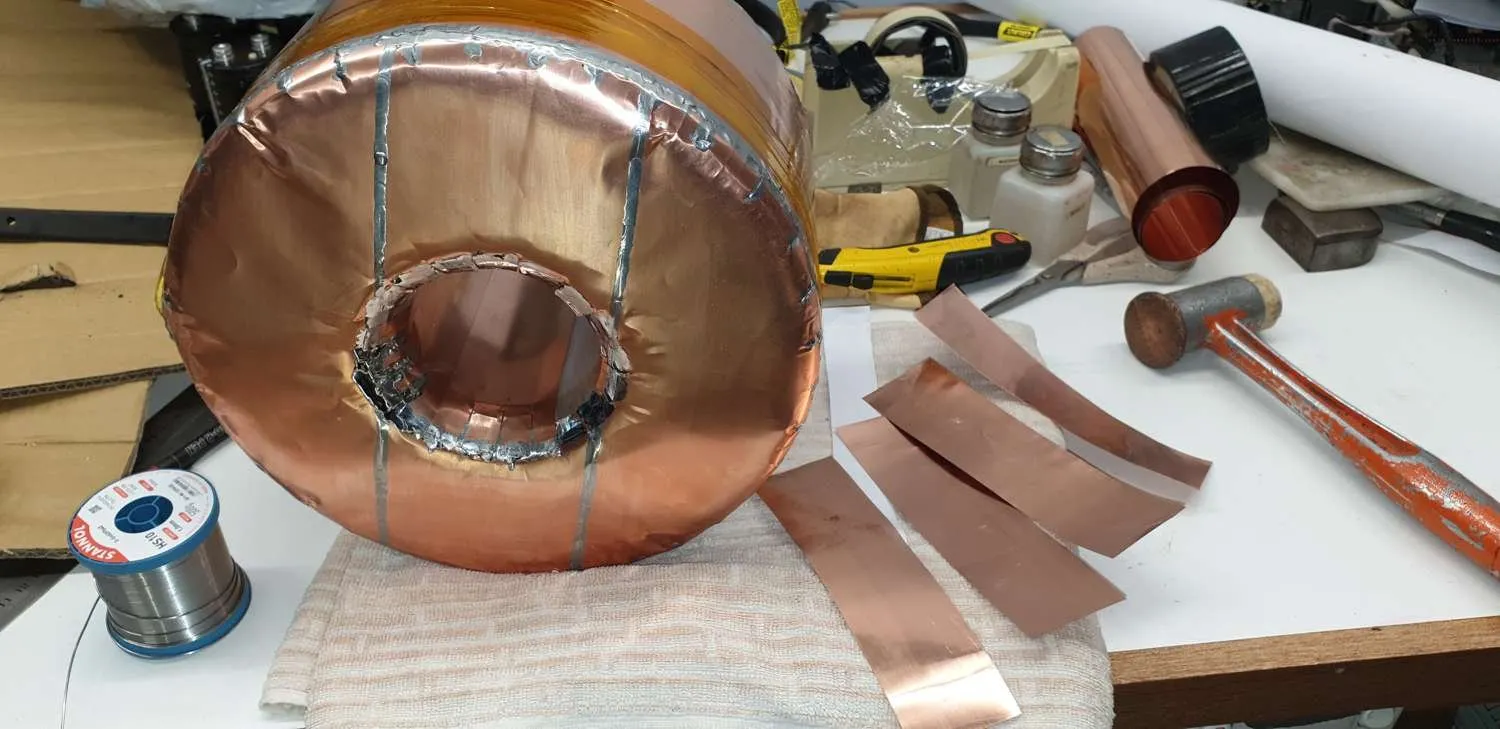

Building a Big Core

Click on photos to open enlarged versions

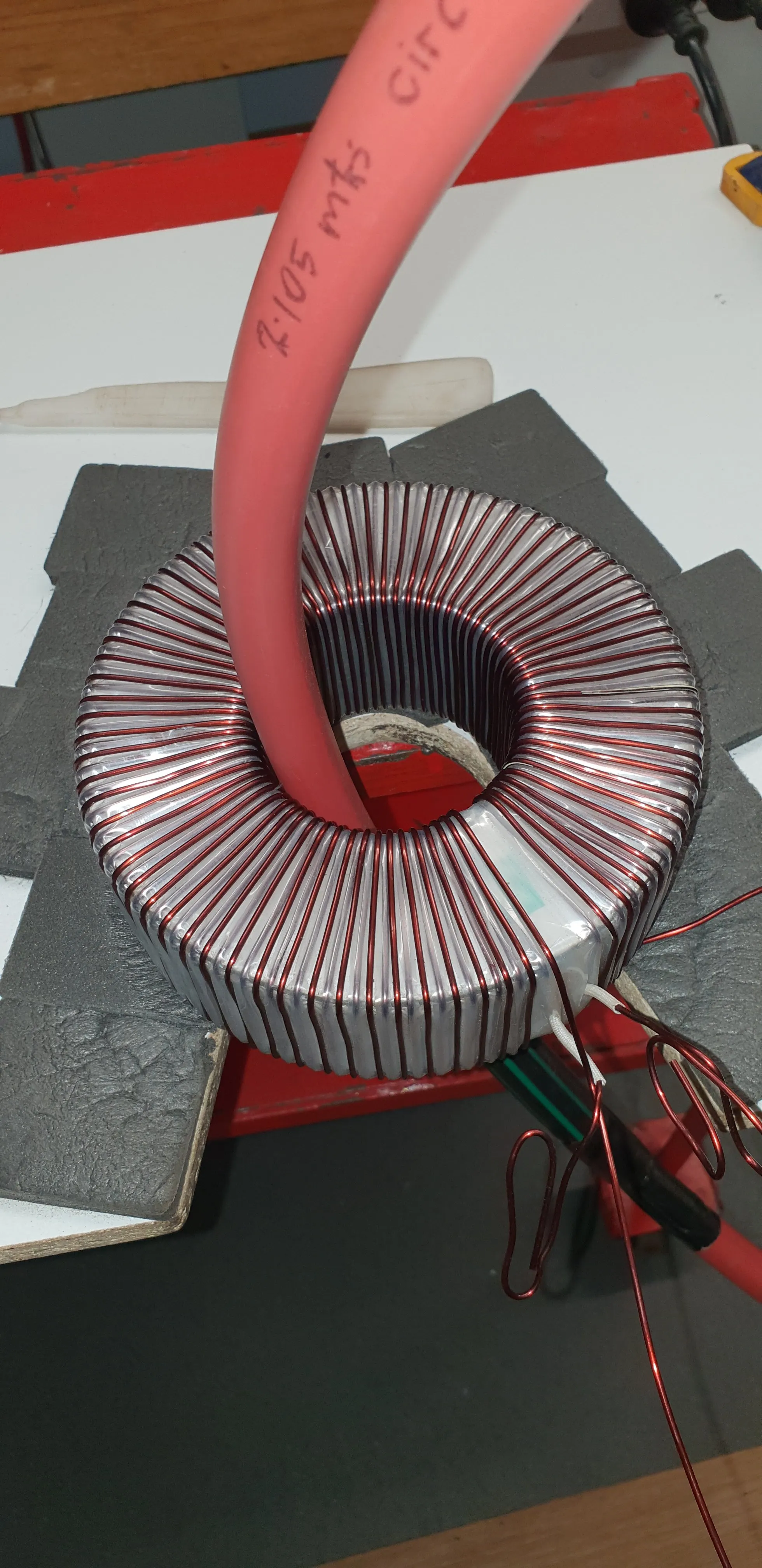

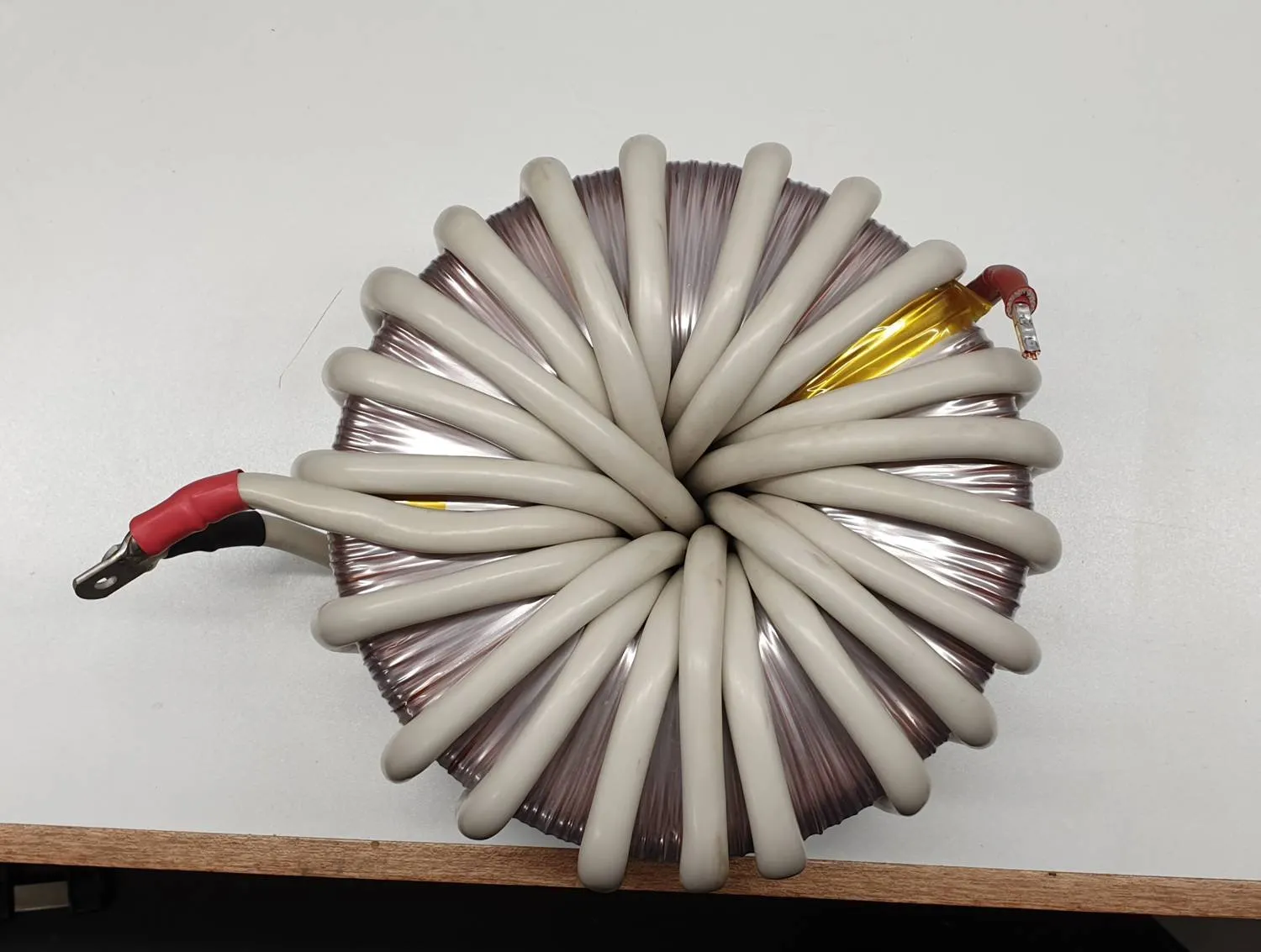

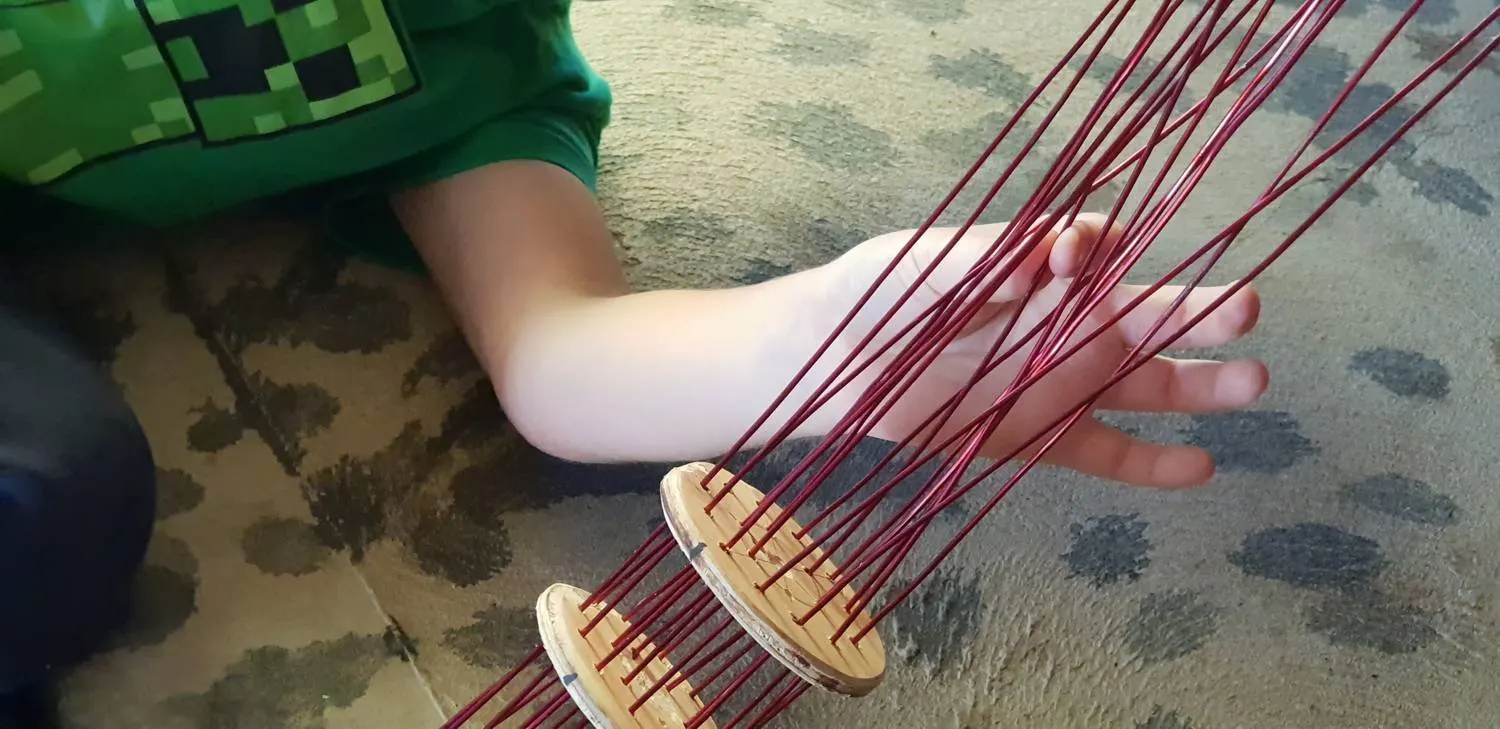

Winding the Big Core

Click on photos to open enlarged versions

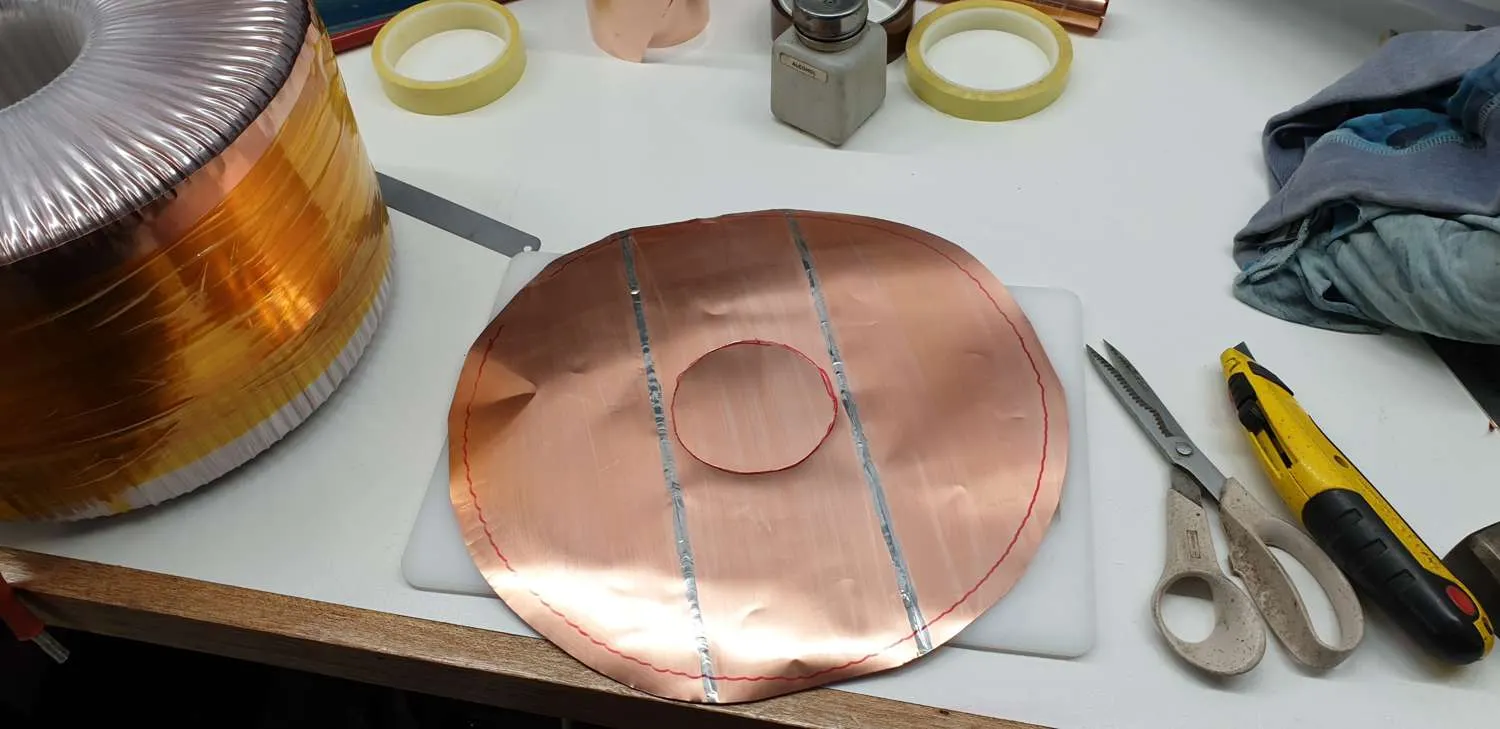

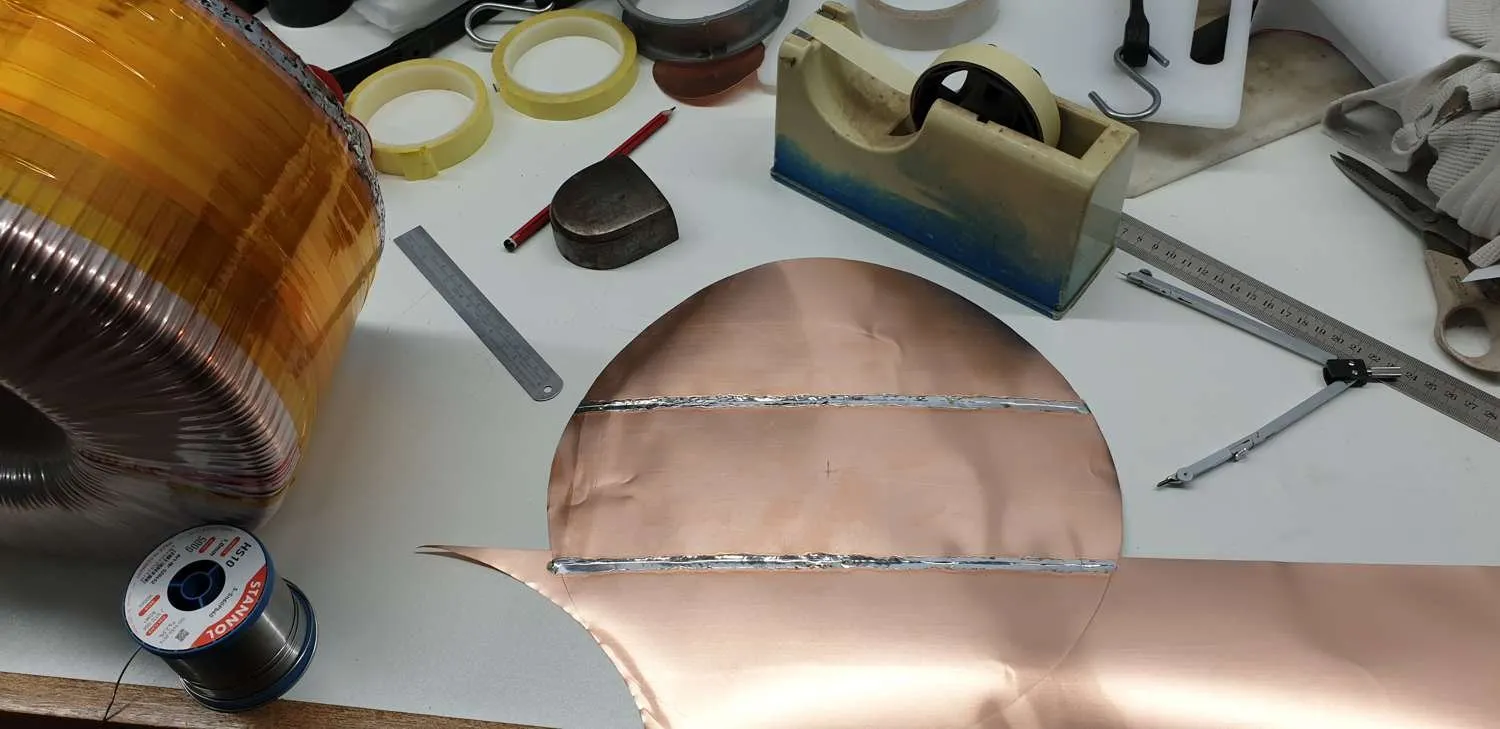

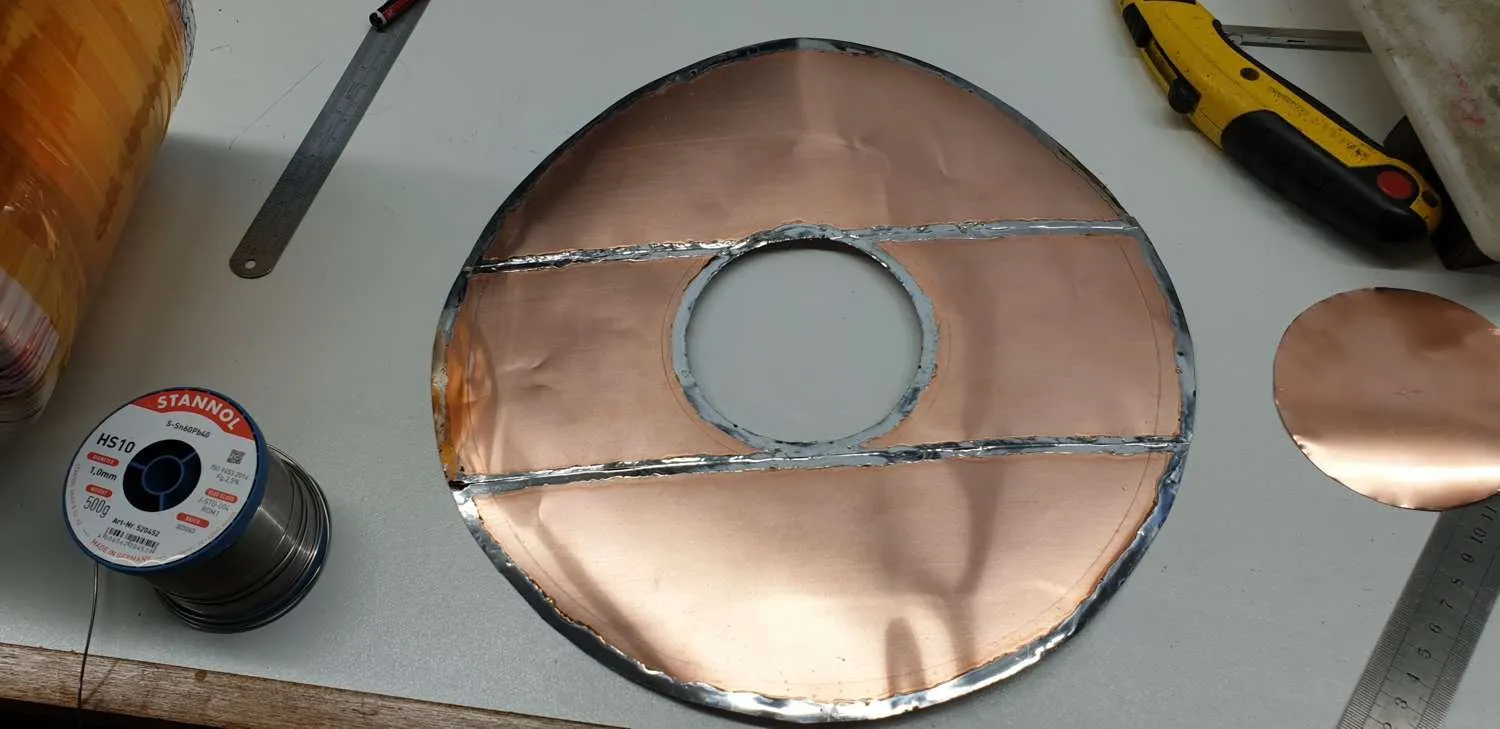

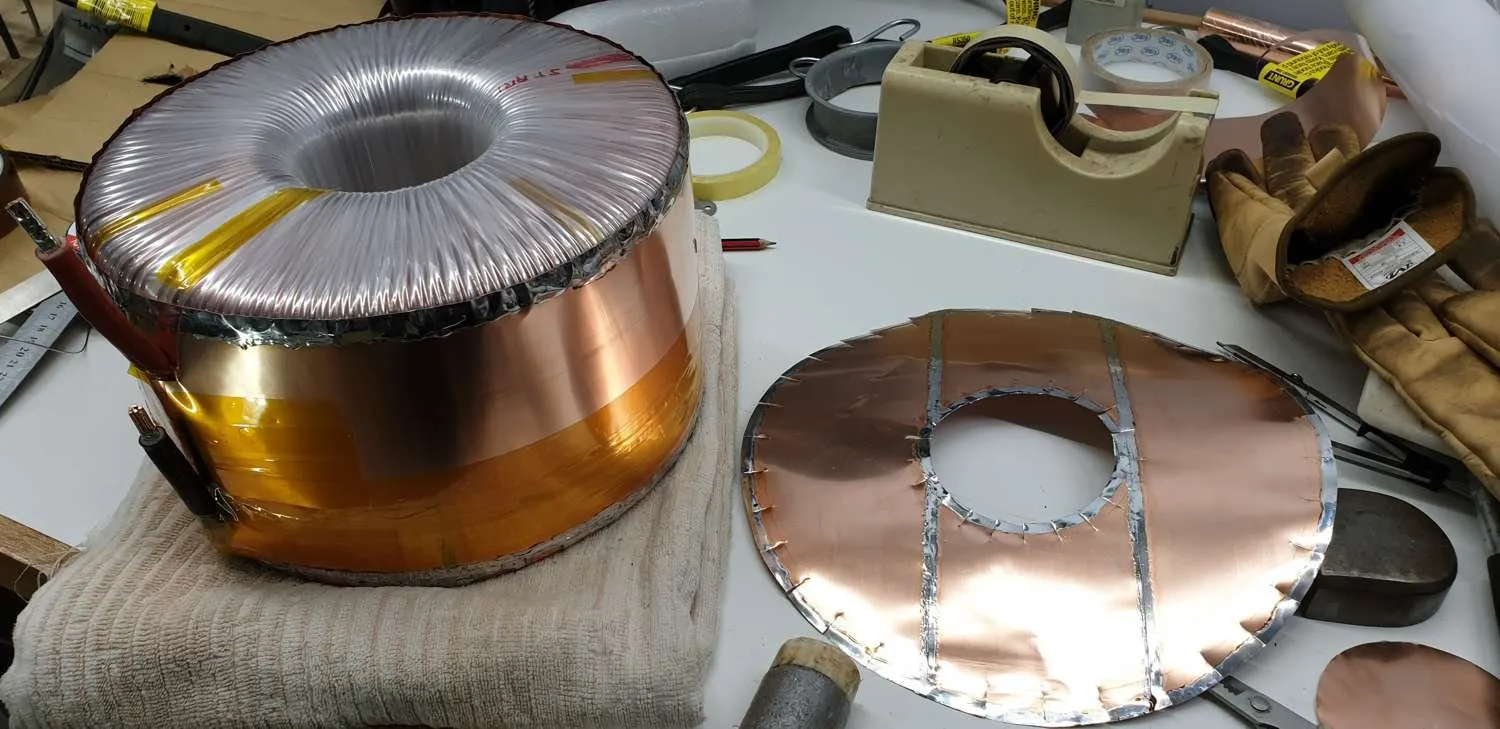

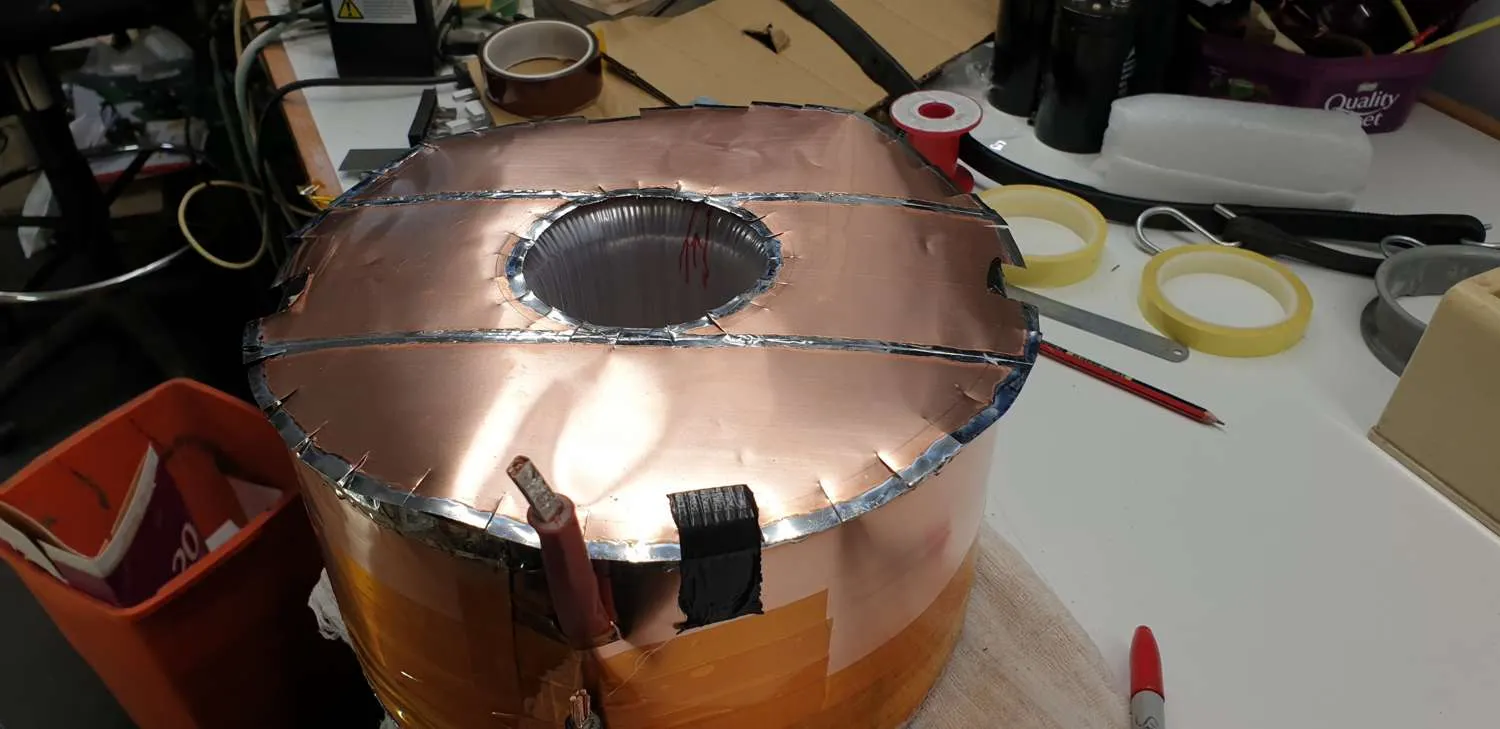

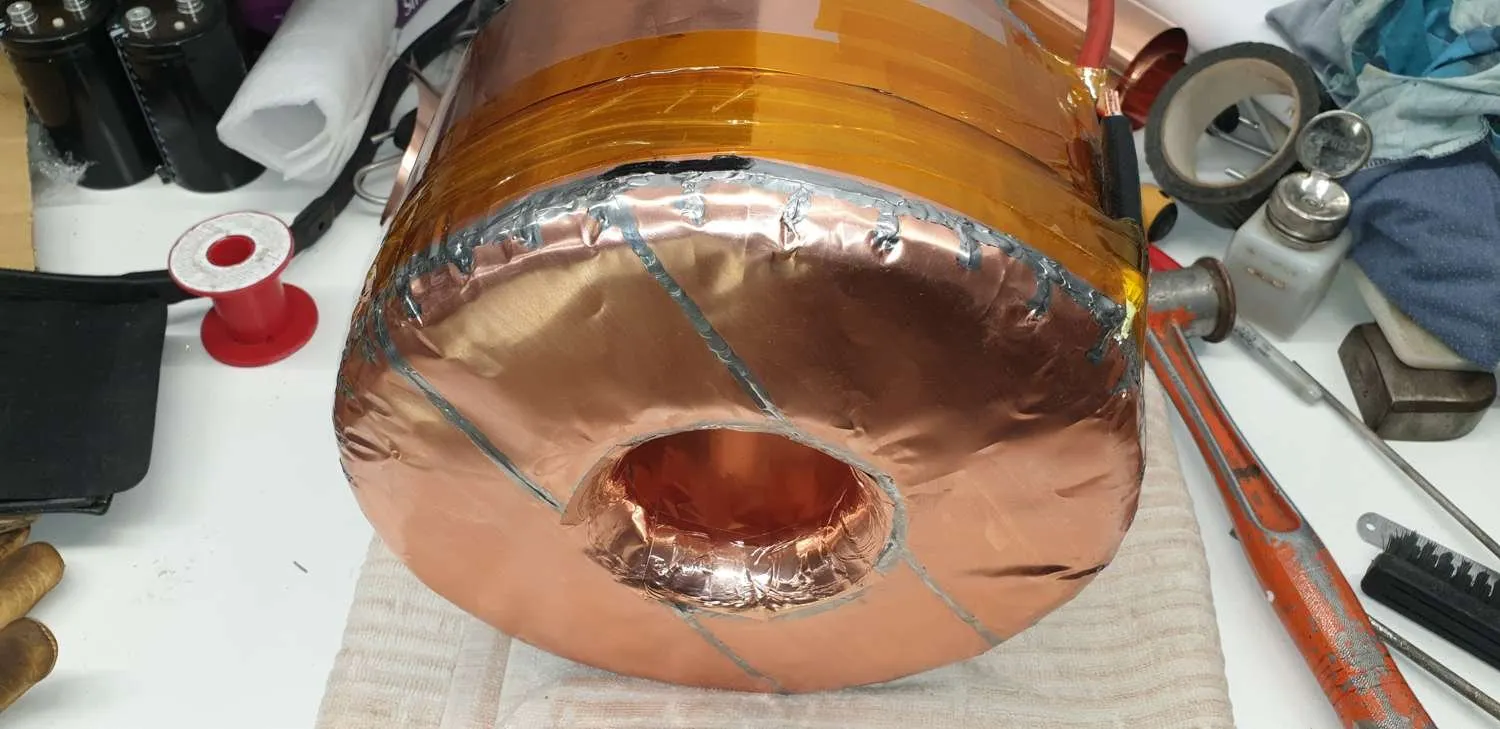

Backtracking to Add Shielding

Click on photos to open enlarged versions

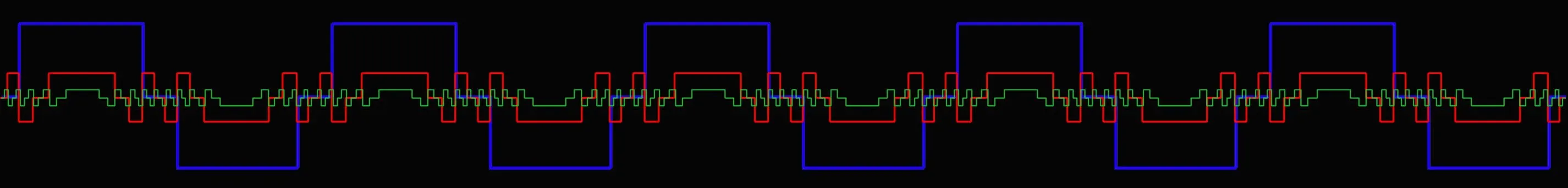

DF-8 ... A Time Saving Tool

Click on photos to open enlarged versions

Contact: Visit this thread on diysolarforum and message Warpspeed or rogerdw

© 2024 Warpverter.com - All Rights Reserved. Terms of Service: Privacy Policy: