Warpverter

A Serious Electronic Project For The Expert DIYer

Builder's Notes

Considering Building a Warpverter?

Decisions to make :

5kW and upwards ... to tens of kW

Below 5kW it is probably better (cheaper, easier) to build an OzInverter or similar

Read Roger's thoughts on his 15kW Warpverter here

While some builders have used 24v, it seems that 48V is probably a realistic minimum. Tony used 100V and there has also been one designed to run from a 200V Toyota Prius battery

No limitations

Certainly for higher power inverters, IGBT modules are probably a better choice ... and for smaller inverter sections, individual IGBT components.

Individual mosfets can also be used, but require more work to assemble and are probably not as robust as IGBT modules

If using 24v or 48v, it may be a toss up between the two.

Just a matter of choosing the correct crystal frequency for your requirements

Can be designed for a wide range of outputs

Yes, can certainly be wound to suit split phase output. See Tony's full explanation here ...

Parts you'll need to source :

Should be able to score one from a scrapped inverter for free or next to nothing.

Warpverters don’t run all that warm so doesn’t need massive cooling … but makes sense to find one big enough to be able to mount all the IGBTs/Mosfets easily ... along with the electrolytic capacitors.

Talk nicely to Tony :)

Gerbers for ordering a circuit board are now available from the downloads page.

Stored energy is proportional to voltage squared, so a very rough ball park figure might be:

48v 5Kw inverter 160,000uF

100v 5Kw inverter 40,000uF (I used three 12,000uF which worked out fine - Tony)

200v 5Kw inverter 10,000uF

200v 2.5Kw inverter 5,000uF

Something like three 1,500uF or 2,200 uF screw terminal low ESR type, one bolted as close as possible across each module would be my choice.

There will be a lot of circulating energy flowing back and forth between the inverters, and a nice clean dc power rail will produce a nice clean ac waveform.

Pay attention to the maximum voltage your batteries may reach and leave a sensible margin for your main filter capacitors. Roger didn't realise that his forklift battery would need to be equalised at 61-62 volts ... and had already built in his 63 volt capacitors. Most definitely should have chosen at least 100v caps

As far as sourcing ... these sort of values can be quite expensive if bought new from mainstream electronics suppliers.

Occasionally reasonable quality ones can be found on eBay or in secondhand equipment ... but they should not be skimped on.

For the pcbs check the downloads page, or download the Half Bridge Power Board gerber files here

You will need to order them via a pcb supply house and while you will only need eight per build, it may pay to order ten.

Components are bog standard parts available from many mainstream component suppliers

These are boards from conventional power adaptors or plug packs.

100-240vac - 15vdc ... though will run quite happily with a much lower DC input supply

The tested start up voltage can vary quite a lot typically from around 30v to 45v or sometimes even higher.

If you are using a 48v or less battery, it may pay to test a few different types before buying them all.

They will need to fire up reliably at the lowest voltage your system is likely to see.

Some have solved this start up voltage issue by buying a 48v-60v dc-dc converter to run them from so they will always power up reliably.

You will need 16 x 15v supplies ... 2 for each of the eight half-bridge boards

And 1 x 5v supply to power the control board.

Check Aliexpress or eBay

This is discussed at length on the "Transformer Sourcing" page.

As mentioned elsewhere the heatsink does not run very warm, though under high load the transformers can begin to warm up.

It would pay to plan for a fan and a small temperature control board and thermistor to monitor transformer and heatsink temperatures, in case one is needed. It will not need to run all the time, but would be wise to have one at the ready.

Barrel fans are available on eBay and aliexpress ... or you may pick one up cheaply or free from the indoor section of a split system airconditioner.

Computer fans are also widely used, though you may need one for the transformers and a second one for the heatsink depending on the layout. These are widely available either new or secondhand.

IGBTs can be bought from all the mainstream electronics suppliers although they can be very expensive. An alternative is to keep an eye on eBay and watch for suitable ones to come up.

Mosfets are available from LCSC Electronics at lcsc.com and both these types are widely used by inverter builders.

There are many other suppliers but LCSC have proven themselves over the last few years. If you find quality parts from other reliable suppliers, please let us know so we can list them here as well.

HY4008W Datasheet 80V/200A

HY5208W Datasheet 80V/320A

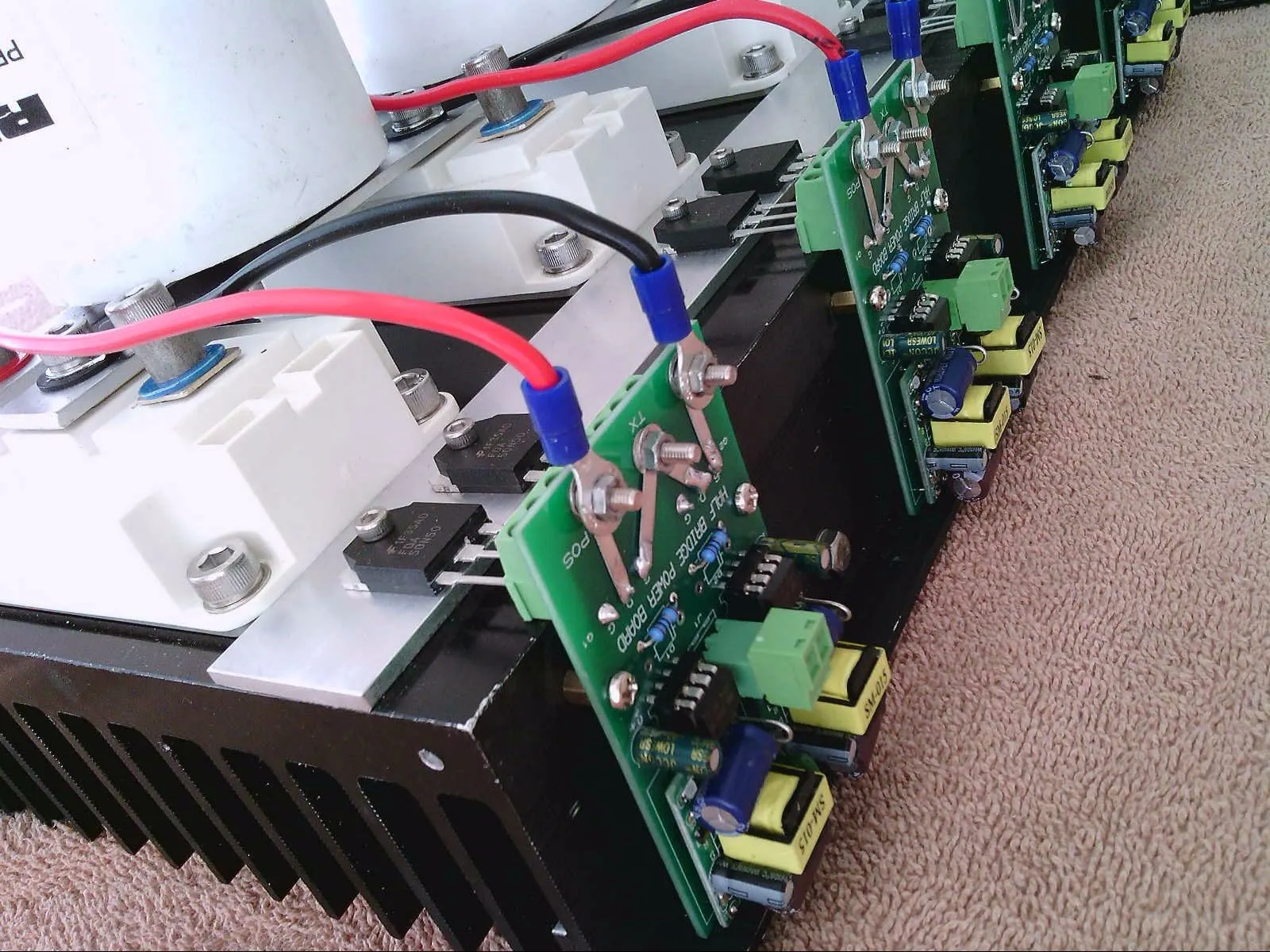

Tony's 5kW Warpverter Output and Heatsink

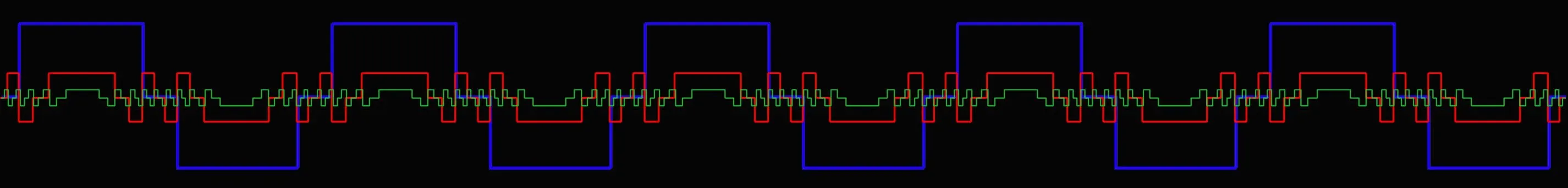

Click Circuits to Open High Resolution Versions

Contact:Visit this thread on diysolarforum and message Warpspeed or rogerdw

© 2024 Warpverter.com - All Rights Reserved. Terms of Service: Privacy Policy: